Coal gas butterfly valve is a commonly used in the metallurgical, chemical and other fields in the ventilation pipe, is mainly responsible for containing dust cold, hot air flow, flow regulation and cut off, so it seems gas butterfly valve does not seem any remarkable, However, compared with the normal valve, butterfly valve structure is more suitable for this work environment.

Product Usage

Coal gas butterfly valve is a commonly used in the metallurgical, chemical and other fields in the ventilation pipe, is mainly responsible for containing dust cold, hot air flow, flow regulation and cut off, so it seems gas butterfly valve does not seem any remarkable, However, compared with the normal valve, butterfly valve structure is more suitable for this work environment.

Gas butterfly valves are made of welded center plate and steel plate, compact structure, light weight. Different from the ordinary type of valve, the characteristic is that it has no internal connection rod, bolts and other structures, so the corridor to bring gas corrosion and destruction have a stronger resistance.

Usually gas butterfly valve will be used pneumatic control or electric control, causing a small torque, easy to operate, high reliability. Therefore, metallurgy, environmental protection and other fields widely used. In addition, this valve can also be manually controlled and automatically switch between the control, to achieve more flexible use.

The use of this butterfly valve, to some extent, can replace the ball valve and gate valve, because there is no need to install multi-layer seals, but directly mounted on the valve body, the seat ring and pressure plate in the middle of the design ring, so to achieve even more ideal Two-way hard seal.

Gas-specific butterfly valve selection principle

1. In the system play the role of connectivity and cut off, and allows a small amount of medium leaks when the media leak (generally not more than 5%) of the damper can be used to close the damper, 74DD round damper, Fang Fengmen, steel shut off damper.

2. In the system play a role in regulating the flow of media, and generally can not afford to cut off the role of the damper, the damper should be used to adjust the damper, steel damper adjustment round. For the requirements of both regulation performance but also need to cut off the function of the media flow damper, should use the leak-free damper damper, 74DD round door, side door. Damper used for centrifugal fan inlet, should only be used to adjust the parallel switch damper, damper door. Used for regulating the role of the need to automatically shut off the occasion of the reverse flow of the throttle, the appropriate choice of anti-stop throttle.

3. In the system for cut off, and does not allow medium leakage (in theory, the amount of leakage is zero), should choose isolated door, the type of standard plug-in door, large gate, flap door, double peaked shutters Style door.

4. Used in the pulverized coal preparation system from the role of isolation throttle, optional pulverized coal gate device.

5. For gray coal dust and other granular materials isolated door, optional isolation gate device.

6. For the dust pipe vulnerable to wear and erosion of the vane damper, the surface to be wear-resistant, corrosion-resistant, optional wear-resistant ceramic door or surface coating of high temperature corrosion-resistant wear-resistant alloy layer damper (throttle life of 16Mn steel Extend the service life of 4 to 5 times).

Specification

Design and manufacture of standards: GB / T 12238-2008

Structure length standard: GB / T 12221-2005

Connection flange standard: GB / T 9113

Pressure temperature grade: GB / T 12224-2005

Test test standards: GB / T 13927-2008

Structural features

1. Quick and easy opening and closing, effort, fluid resistance, you can often operate.

2. Simple structure, small size, light weight.

3. To achieve a good seal under low pressure.

4. Adjust the performance.

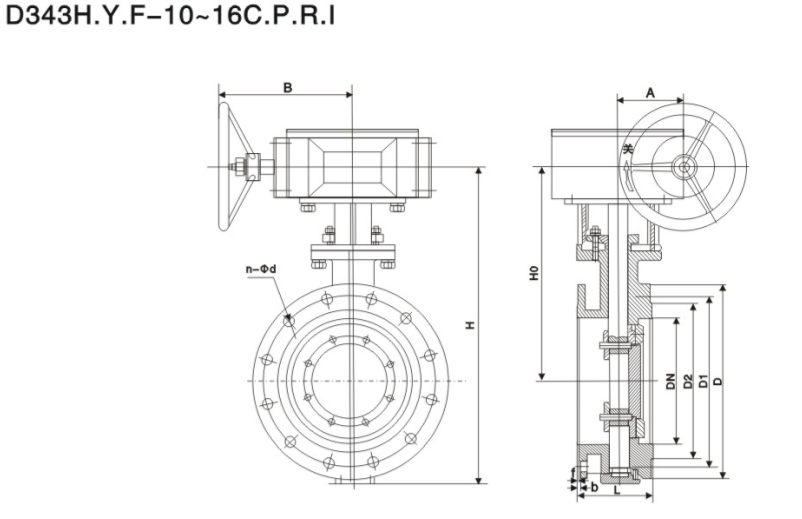

The main shape and connection size

|

PN |

DN |

L |

D |

D1 |

D2 |

Z-d |

b |

f |

H |

H0 |

|

1.0 |

50 |

108 |

165 |

125 |

99 |

4-18 |

20 |

2 |

170 |

130 |

|

1.0 |

65 |

112 |

185 |

145 |

118 |

4-18 |

20 |

2 |

170 |

145 |

|

1.0 |

80 |

114 |

200 |

160 |

132 |

8-18 |

20 |

2 |

230 |

152 |

|

1.0 |

100 |

127 |

220 |

180 |

156 |

8-18 |

22 |

2 |

320 |

192 |

|

1.0 |

125 |

140 |

250 |

210 |

184 |

8-18 |

22 |

2 |

345 |

200 |

|

1.0 |

150 |

140 |

285 |

240 |

211 |

8-22 |

24 |

2 |

385 |

230 |

|

1.0 |

200 |

152 |

340 |

295 |

266 |

8-22 |

24 |

2 |

471 |

297 |

|

1.0 |

250 |

165 |

405 |

355 |

319 |

12-22 |

26 |

2 |

533 |

327 |

|

1.0 |

300 |

178 |

445 |

400 |

370 |

12-22 |

26 |

2 |

606 |

364 |

|

1.0 |

350 |

190 |

505 |

460 |

429 |

16-22 |

26 |

2 |

694 |

404 |

|

1.0 |

400 |

216 |

565 |

515 |

480 |

16-26 |

26 |

2 |

757 |

444 |

|

1.0 |

450 |

222 |

615 |

565 |

530 |

20-26 |

28 |

2 |

814 |

472 |

|

1.0 |

500 |

229 |

670 |

620 |

582 |

20-26 |

28 |

2 |

902 |

522 |

|

1.0 |

600 |

267 |

780 |

725 |

682 |

20-30 |

34 |

2 |

1048 |

590 |

|

1.0 |

700 |

292 |

895 |

840 |

794 |

24-30 |

34 |

5 |

1277 |

810 |

|

1.0 |

800 |

318 |

1015 |

950 |

901 |

24-33 |

36 |

5 |

1385 |

844 |

|

1.0 |

900 |

330 |

1115 |

1050 |

1001 |

28-33 |

38 |

5 |

1490 |

890 |

|

1.0 |

1000 |

410 |

1230 |

1160 |

1112 |

28-36 |

38 |

5 |

1620 |

950 |

|

1.6 |

50 |

108 |

165 |

125 |

99 |

4-18 |

20 |

2 |

170 |

130 |

|

1.6 |

65 |

112 |

185 |

145 |

118 |

4-18 |

20 |

2 |

170 |

145 |

|

1.6 |

80 |

114 |

200 |

160 |

132 |

8-18 |

20 |

2 |

230 |

152 |

|

1.6 |

100 |

127 |

220 |

180 |

156 |

8-18 |

22 |

2 |

320 |

192 |

|

1.6 |

125 |

140 |

250 |

210 |

184 |

8-18 |

22 |

2 |

345 |

200 |

|

1.6 |

150 |

140 |

285 |

240 |

211 |

8-22 |

24 |

2 |

385 |

230 |

|

1.6 |

200 |

152 |

340 |

295 |

266 |

12-22 |

24 |

2 |

471 |

297 |

|

1.6 |

250 |

165 |

405 |

355 |

319 |

12-26 |

26 |

2 |

533 |

327 |

|

1.6 |

300 |

178 |

460 |

410 |

370 |

12-26 |

28 |

2 |

606 |

364 |

|

1.6 |

350 |

190 |

520 |

470 |

429 |

16-26 |

30 |

2 |

694 |

404 |

|

1.6 |

400 |

216 |

580 |

525 |

480 |

16-30 |

32 |

2 |

757 |

444 |

|

1.6 |

450 |

222 |

640 |

585 |

548 |

20-30 |

40 |

2 |

814 |

472 |

|

1.6 |

500 |

229 |

715 |

650 |

609 |

20-33 |

44 |

2 |

902 |

522 |

|

1.6 |

600 |

267 |

840 |

770 |

720 |

20-36 |

54 |

2 |

1048 |

590 |

|

1.6 |

700 |

292 |

910 |

840 |

794 |

24-36 |

40 |

5 |

1277 |

810 |

|

1.6 |

800 |

318 |

1025 |

950 |

901 |

24-39 |

42 |

5 |

1385 |

844 |

|

1.6 |

900 |

330 |

1125 |

1050 |

1001 |

28-39 |

44 |

5 |

1490 |

890 |

|

1.6 |

1000 |

410 |

1225 |

1170 |

1112 |

28-42 |

46 |

5 |

1620 |

950 |

|

2.5 |

50 |

108 |

165 |

125 |

99 |

4-18 |

20 |

2 |

170 |

130 |

|

2.5 |

65 |

112 |

185 |

145 |

118 |

8-18 |

22 |

2 |

265 |

210 |

|

2.5 |

80 |

114 |

200 |

160 |

132 |

8-18 |

24 |

2 |

310 |

233 |

|

2.5 |

100 |

127 |

235 |

190 |

156 |

8-22 |

24 |

2 |

343 |

242 |

|

2.5 |

125 |

140 |

270 |

220 |

184 |

8-26 |

26 |

2 |

385 |

254 |

|

2.5 |

150 |

140 |

300 |

250 |

211 |

8-26 |

28 |

2 |

445 |

580 |

|

2.5 |

200 |

152 |

360 |

310 |

274 |

12-26 |

30 |

2 |

510 |

297 |

|

2.5 |

250 |

165 |

425 |

370 |

330 |

12-30 |

32 |

2 |

569 |

339 |

|

2.5 |

300 |

178 |

485 |

430 |

389 |

16-30 |

34 |

2 |

653 |

375 |

|

2.5 |

350 |

190 |

555 |

490 |

448 |

16-33 |

38 |

2 |

730 |

420 |

|

2.5 |

400 |

216 |

620 |

550 |

503 |

16-36 |

40 |

2 |

810 |

463 |

|

2.5 |

450 |

222 |

670 |

600 |

548 |

20-36 |

46 |

2 |

850 |

495 |

|

2.5 |

500 |

229 |

730 |

660 |

609 |

20-36 |

48 |

2 |

940 |

566 |

|

2.5 |

600 |

267 |

845 |

770 |

720 |

20-39 |

58 |

2 |

1150 |

630 |

|

2.5 |

700 |

292 |

960 |

875 |

820 |

24-42 |

58 |

5 |

1195 |

727 |

|

2.5 |

800 |

318 |

1085 |

990 |

609 |

24-36 |

58 |

5 |

1268 |

810 |

Structure picture

If you have any enquiry about quotation or cooperation,please feel free to email us at info@cnlgvalve.com or use the following enquiry form. Our sales representative will contact you within 24 hours. Thank you for your interest in our products.