Gate valve is one of the most widely used valves in various fluid transportation projects. Traditional gate valves generally have phenomena such as easy fluid leakage and serious corrosion of internal parts. In the ordinary soft seal gate valves on the market, the stem shaft seal is easy to leak, and it is impossible to replace the sealing ring under continuous water and at any opening degree.

Product Description

Features

Executive Standard

1. Valve design and manufacturing according to GB / 24924-2010 standards;

2. The length of the valve structure according to the provisions of GB / T12221-2005;

3. Inspection and testing should be consistent with the relevant provisions of GB / T13927-2008;

4. Flange size according to the provisions of GB / T17241.6-2008;

Technical Parameters

|

Nominal size |

DN40~DN800 |

||

|

Suitable media |

Clear water, or similar physical and chemical properties of water medium

(Sewage, raw water, hot water, oil medium, please specify)

|

||

|

Operating temperature℃ |

0-70 (standard configuration) 0-100 (hot water configuration) |

||

|

Nominal pressure |

PN10 |

PN16 |

PN25 |

|

Work pressure(MPa) |

≤1.00 |

≤1.60 |

≤2.50 |

|

Strength test(MPa) |

1.50 |

2.40 |

3.75 |

|

Seal test(MPa) |

1.10 |

1.76 |

2.75 |

|

Low pressure test(MPa) |

0.02 |

0.02 |

0.02 |

|

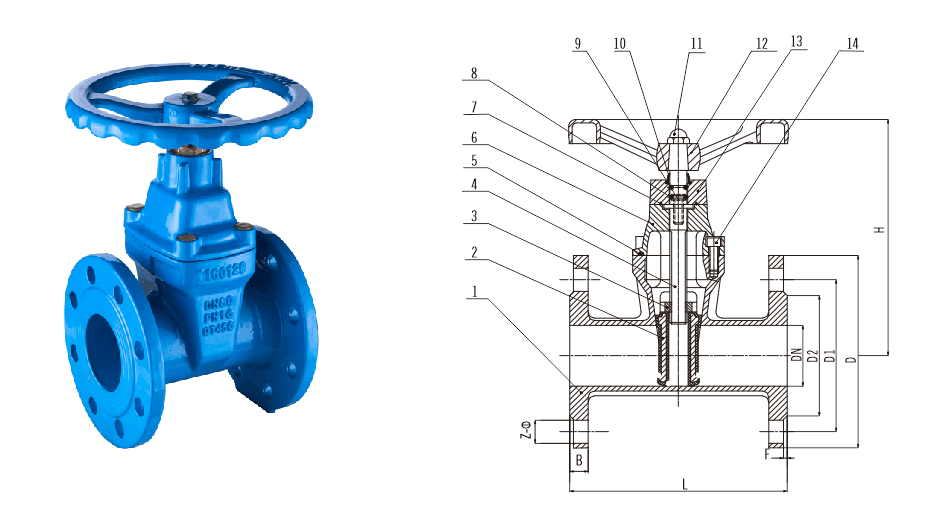

Serial number |

name |

material |

|

1 |

Body |

QT450 |

|

2 |

Valve plate |

QT450+NBR |

|

3 |

Stem nut |

QT450 |

|

4 |

Valve stem |

20Cr13 |

|

5 |

Flange seals |

NBR |

|

6 |

cap |

QT450 |

|

7 |

O-ring |

NBR |

|

8 |

O-ring |

NBR |

|

9 |

Countersunk head bolt |

35# |

|

10 |

Dust cover |

NBR |

|

11 |

Round head screw |

35# |

|

12 |

Handwheel |

QT450 |

|

13 |

Gland |

QT450 |

|

14 |

Countersunk head bolt |

35# |

The main shape and connection dimensions

|

Nominal diameter |

The main dimensions and connection dimensions |

|||||||

|

L |

D |

D1 |

D2 |

C |

F |

Z-d |

H |

|

|

Z45X-10Q |

||||||||

|

40 |

165 |

150 |

110 |

84 |

19 |

3 |

4-Φ19 |

240 |

|

50 |

178 |

165 |

125 |

99 |

19 |

3 |

4-Φ19 |

240 |

|

65 |

190 |

185 |

145 |

118 |

19 |

3 |

4-Φ19 |

260 |

|

80 |

203 |

200 |

160 |

132 |

19 |

3 |

8-Φ19 |

275 |

|

100 |

229 |

220 |

180 |

156 |

19 |

3 |

8-Φ19 |

380 |

|

125 |

254 |

250 |

210 |

184 |

19 |

3 |

8-Φ19 |

410 |

|

150 |

267 |

285 |

240 |

221 |

19 |

3 |

8-Φ23 |

435 |

|

200 |

292 |

340 |

295 |

266 |

20 |

3 |

8-Φ23 |

630 |

|

250 |

330 |

395 |

350 |

319 |

22 |

3 |

12-Φ23 |

645 |

|

300 |

356 |

445 |

400 |

370 |

24.5 |

4 |

12-Φ23 |

697 |

|

350 |

381 |

505 |

460 |

429 |

24.5 |

4 |

16-Φ23 |

802 |

|

400 |

406 |

565 |

515 |

480 |

24.5 |

4 |

16-Φ28 |

842 |

|

450 |

432 |

615 |

565 |

530 |

25.5 |

4 |

20-Φ28 |

1060 |

|

500 |

457 |

670 |

620 |

582 |

26.5 |

4 |

20-Φ28 |

1170 |

|

600 |

508 |

780 |

725 |

682 |

30 |

5 |

20-Φ31 |

1300 |

|

700 |

610 |

895 |

840 |

794 |

32.5 |

5 |

24-Φ31 |

1550 |

|

800 |

660 |

1015 |

950 |

901 |

35 |

5 |

24-Φ34 |

1750 |

|

900 |

711 |

1115 |

1050 |

1001 |

37.5 |

5 |

28-Φ34 |

1950 |

|

1000 |

811 |

1230 |

1160 |

1112 |

40 |

5 |

28-Φ37 |

2170 |

|

Z45X-16Q |

||||||||

|

40 |

165 |

150 |

110 |

84 |

19 |

3 |

4-Φ19 |

240 |

|

50 |

178 |

165 |

125 |

99 |

19 |

3 |

4-Φ19 |

240 |

|

65 |

190 |

185 |

145 |

118 |

19 |

3 |

4-Φ19 |

260 |

|

80 |

203 |

200 |

160 |

132 |

19 |

3 |

8-Φ19 |

275 |

|

100 |

229 |

220 |

180 |

156 |

19 |

3 |

8-Φ19 |

380 |

|

125 |

254 |

250 |

210 |

184 |

19 |

3 |

8-Φ19 |

410 |

|

150 |

267 |

285 |

240 |

221 |

19 |

3 |

8-Φ23 |

435 |

|

200 |

292 |

340 |

295 |

266 |

20 |

3 |

12-Φ23 |

630 |

|

250 |

330 |

405 |

355 |

319 |

22 |

3 |

12-Φ28 |

645 |

|

300 |

356 |

460 |

410 |

370 |

24.5 |

4 |

12-Φ28 |

697 |

|

350 |

381 |

520 |

470 |

429 |

26.5 |

4 |

16-Φ28 |

802 |

|

400 |

406 |

580 |

525 |

480 |

28 |

4 |

16-Φ31 |

842 |

|

450 |

432 |

640 |

585 |

548 |

30 |

4 |

20-Φ31 |

1060 |

|

500 |

457 |

715 |

650 |

609 |

31.5 |

4 |

20-Φ34 |

1170 |

|

600 |

508 |

840 |

770 |

720 |

36 |

5 |

20-Φ37 |

1300 |

|

700 |

610 |

910 |

840 |

794 |

39.5 |

5 |

24-Φ37 |

1550 |

|

800 |

660 |

1025 |

950 |

901 |

43 |

5 |

24-Φ40 |

1750 |

|

900 |

711 |

1125 |

1050 |

1001 |

46.5 |

5 |

28-Φ40 |

1950 |

|

1000 |

811 |

1255 |

1170 |

1112 |

50 |

5 |

28-Φ43 |

2170 |

Structure picture

If you have any enquiry about quotation or cooperation,please feel free to email us at info@cnlgvalve.com or use the following enquiry form. Our sales representative will contact you within 24 hours. Thank you for your interest in our products.