The stainless steel gate valve produced by Lianggu valve Co., Ltd. The valve body, valve cover, gate plate, gate rod are made of stainless steel. The valve seat sealing surface is PTFE, stainless steel + carbide or surfacing carbide. The filler is carbide, PTFE, asbestos or flexible graphite. Nominal size DN15 ~ DN800, working pressure 1.6MPa ~ 20.0MPa, applicable temperature ≤ 200 ℃, suitable for nitric acid, weakly corrosive medium pipeline.

Product Usage

The stainless steel gate valve produced by Lianggu valve Co., Ltd. The valve body, valve cover, gate plate, gate rod are made of stainless steel. The valve seat sealing surface is PTFE, stainless steel + carbide or surfacing carbide. The filler is carbide, PTFE, asbestos or flexible graphite. Nominal size DN15 ~ DN800, working pressure 1.6MPa ~ 20.0MPa, applicable temperature ≤ 200 ℃, suitable for nitric acid, weakly corrosive medium pipeline.

Features

1. Using austenitic stainless steel which has good corrosion resistance to oxidizing acid medium.

2. When the medium flows through the stainless steel gate valve, the flow direction is not changed and the fluid resistance is small.

3. The movement direction of the gate is perpendicular to the flow direction of the medium, the opening and closing torque is small, and the opening and closing are labor-saving.

4. The flow direction of the medium is not limited. It will not disturb the flow or reduce the pressure. The medium can flow from any direction on both sides of the gate valve, which can achieve the purpose of use. It is most suitable for pipelines where the medium flow direction may change.

5. The gate is placed vertically in the valve body, the structure length is short..

6. Good sealing performance. The sealing surface is less eroded when fully opened.

Executive Standard

Design specifications: GB / T 12234

Structure length: GB / T 12221

Connecting flange: JB / T 79.1

Test and inspection: JB / T 9092

Pressure - Temperature: GB / T 9131

Product Identification: GB / T 12220

Performance parameters

|

Nominal pressurePN(MPa) |

case |

test pressure(MPa) |

Sealed |

|

|

Sealed (liquid) |

Seal (gas) |

|||

|

1.6 |

2.4 |

1.8 |

0.6 |

1.8 |

|

2.5 |

3.8 |

2.8 |

0.6 |

2.8 |

|

4.0 |

6.0 |

4.4 |

0.6 |

4.4 |

|

6.4 |

9.6 |

7.0 |

0.6 |

7.0 |

|

10.0 |

15.0 |

11.0 |

0.6 |

11.0 |

|

16.0 |

24.0 |

18.0 |

0.6 |

18.0 |

Suitable medium and applicable temperature

|

Shell material |

Suitable media |

Applicable temperature (℃) |

|

Chromium nickel titanium steel (P type) |

Nitric acids |

≤200 |

|

Chrome nickel molybdenum titanium steel (R type) |

Acetic acid |

≤200 |

The main part material

|

Body, bonnet |

Valve plate, seat |

Valve stem |

Stem nut |

filler |

Handwheel |

|

Chromium nickel titanium steel |

Stainless steel, stainless steel + cemented carbide |

Chrome nickel-titanium stainless steel |

Aluminum bronze |

Teflon |

Malleable iron |

|

Chromium nickel molybdenum titanium steel |

Stainless steel, stainless steel + cemented carbide |

Chrome nickel-titanium stainless steel |

Aluminum bronze |

Teflon |

Malleable iron |

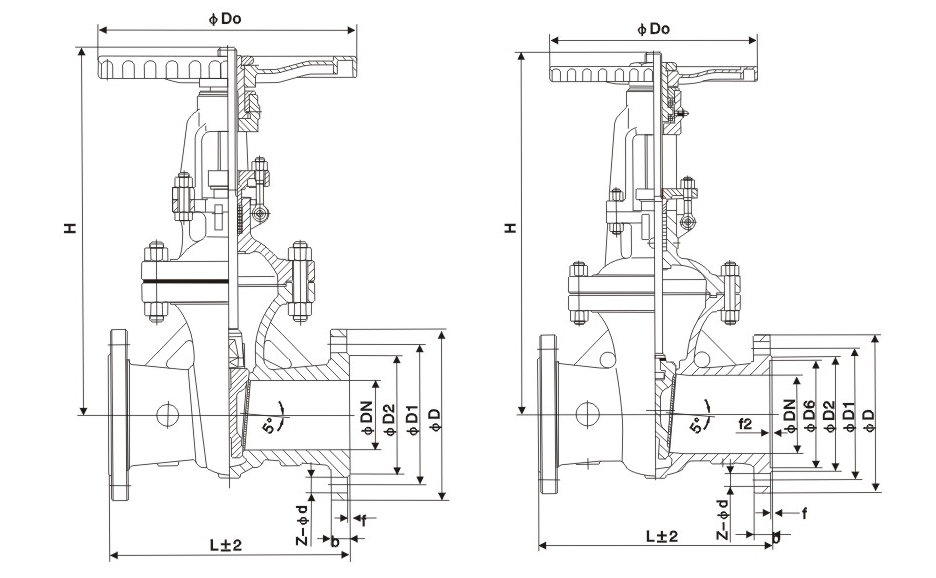

The main shape and connection dimensions

|

Nominal diameter |

The main dimensions and connection dimensions |

|||||||

|

L |

D |

D1 |

D2 |

b |

Z-d |

H |

D0 |

|

|

Z41W-16P |

||||||||

|

15 |

130 |

95 |

65 |

45 |

14-2 |

4-Φ14 |

170 |

120 |

|

20 |

150 |

105 |

75 |

55 |

14-2 |

4-Φ14 |

190 |

140 |

|

25 |

160 |

115 |

85 |

65 |

14-2 |

4-Φ14 |

205 |

160 |

|

32 |

180 |

135 |

100 |

78 |

16-2 |

4-Φ18 |

270 |

180 |

|

40 |

200 |

145 |

110 |

85 |

16-3 |

4-Φ18 |

310 |

200 |

|

50 |

250 |

160 |

125 |

100 |

16-3 |

4-Φ18 |

358 |

240 |

|

65 |

265 |

180 |

145 |

120 |

18-3 |

4-Φ18 |

373 |

240 |

|

80 |

280 |

195 |

160 |

135 |

20-3 |

8-Φ18 |

435 |

280 |

|

100 |

300 |

215 |

180 |

155 |

20-3 |

8-Φ18 |

500 |

300 |

|

125 |

325 |

245 |

210 |

185 |

22-3 |

8-Φ18 |

614 |

320 |

|

150 |

350 |

280 |

240 |

210 |

24-3 |

8-Φ23 |

674 |

360 |

|

200 |

400 |

335 |

295 |

265 |

26-3 |

12-Φ23 |

811 |

400 |

|

250 |

450 |

405 |

355 |

320 |

30-3 |

12-Φ25 |

969 |

450 |

|

300 |

500 |

460 |

410 |

375 |

30-3 |

12-Φ25 |

1145 |

580 |

|

350 |

550 |

520 |

470 |

435 |

34-4 |

16-Φ25 |

1280 |

640 |

|

400 |

600 |

580 |

525 |

485 |

36-4 |

16-Φ30 |

1452 |

640 |

|

Z41W-25P |

||||||||

|

15 |

130 |

95 |

65 |

45 |

16-2 |

4-Φ14 |

170 |

120 |

|

20 |

150 |

105 |

75 |

55 |

16-2 |

4-Φ14 |

190 |

140 |

|

25 |

160 |

115 |

85 |

65 |

16-2 |

4-Φ14 |

205 |

160 |

|

32 |

180 |

135 |

100 |

78 |

18-2 |

4-Φ18 |

270 |

180 |

|

40 |

200 |

145 |

110 |

85 |

18-3 |

4-Φ18 |

310 |

200 |

|

50 |

250 |

160 |

125 |

100 |

20-3 |

4-Φ18 |

358 |

240 |

|

65 |

265 |

180 |

145 |

120 |

22-3 |

8-Φ18 |

373 |

240 |

|

80 |

280 |

195 |

160 |

135 |

22-3 |

8-Φ18 |

435 |

280 |

|

100 |

300 |

230 |

190 |

160 |

24-3 |

8-Φ23 |

500 |

300 |

|

125 |

325 |

270 |

220 |

188 |

28-3 |

8-Φ25 |

614 |

320 |

|

150 |

350 |

300 |

250 |

218 |

30-3 |

8-Φ25 |

674 |

360 |

|

200 |

400 |

360 |

310 |

278 |

34-3 |

12-Φ25 |

811 |

400 |

|

250 |

450 |

425 |

370 |

332 |

36-3 |

12-Φ30 |

969 |

450 |

|

300 |

500 |

485 |

430 |

390 |

40-4 |

16-Φ30 |

1145 |

580 |

|

350 |

550 |

550 |

490 |

448 |

44-4 |

16-Φ34 |

1280 |

640 |

|

400 |

600 |

610 |

550 |

505 |

48-4 |

16-Φ34 |

1452 |

640 |

Structure picture

If you have any enquiry about quotation or cooperation,please feel free to email us at info@cnlgvalve.com or use the following enquiry form. Our sales representative will contact you within 24 hours. Thank you for your interest in our products.