Liquid-controlled butterfly valve is a butterfly valve, liquid-controlled butterfly valve sub-pressure-type, lock-type and energy-saving three. It applies to the pump outlet and turbine inlet piping, as a closed-circuit and check valve, used to avoid and reduce the piping system in the media backflow and excessive water hammer to protect the piping system.

Product Usage

Liquid-controlled butterfly valve is a butterfly valve, liquid-controlled butterfly valve sub-pressure-type, lock-type and energy-saving three. It applies to the pump outlet and turbine inlet piping, as a closed-circuit and check valve, used to avoid and reduce the piping system in the media backflow and excessive water hammer to protect the piping system.

Specification

Design and manufacture of standards: GB / T 12238-2008

Structure length standard: GB / T 12221-2005

Connection flange standard: GB / T 9113

Pressure temperature grade: GB / T 12224-2005

Test test standards: GB / T 13927-2008

Structural features

The pressure-type, locking-type liquid-controlled butterfly valve, driven by hydraulic drive, can be closed by the weight of the hammer. After the valve is installed, it can replace the gate valve (butterfly valve) and check valve, and the flow resistance coefficient is small. Valve closing time and speed of two stages, the first paragraph for the fast off, the latter part of the slow off, and can be adjusted according to user needs fast and slow closing time and angle, pressure-type hydraulic system with open valve automatically holding pressure and automatic reset function. Locked with dual automatic locking and locking pin locking. Accumulator liquid-controlled butterfly valve open by the pump, and closed by the accumulator. As a result of the accumulator off the valve, thus eliminating the weight, so take up space, easy installation, compact structure. Electrical control can be based on user needs common type control and PLC control, to achieve the valve linkage, and remote control can be achieved in situ and computer control.

【Main performance specifications

|

Nominal diameter |

DN(mm) |

50-4000 |

||

|

Nominal pressure |

PN(MPa) |

1.0 |

1.6 |

2.5 |

|

test pressure |

Strength test |

1.5 |

2.4 |

3.75 |

|

Seal test |

1.1 |

1.76 |

2.75 |

|

|

Gas seal test |

0.6 |

0.6 |

0.6 |

|

Principle

1) Open the valve: hydraulic butterfly valve open, the use of hydraulic control station and the lifting cylinder force, through the arm, hammer rod, valve shaft and other components, driven by 90 ° rotation of the disc. At the same time, the hydraulic control station and the lifting cylinder also elevates the weight vertically by lifting the arm and the weight rod, converts the weight of the weight to potential energy, and prepares for closing the valve.

2) Locking: The locking mechanism of the liquid-controlled butterfly valve is composed of transmission cylinder, mechanical locking shaft, electromagnetic locking shaft, electromagnet and other components. It has the function of mechanical electromagnetic interlocking. When the valve is fully open, the driving force of the transmission cylinder drives the machine The locking shaft is put into the locking position for the initial locking, and then the electromagnetic locking shaft is driven by the electromagnetic force of the electromagnet to perform the final locking. The locking process is performed automatically and completely in a series of switches under the action of a series of switches. The huge force of the hammer is completely affected by the mechanical lock bearing. The withdrawal of the mechanical lock shaft is restricted by the electromagnetic lock shaft. The withdrawal of the electromagnetic lock shaft is controlled by the electromagnetic force of the electromagnet. As long as the electromagnet does not lose electricity, its electromagnetic lock The shaft and the mechanical locking shaft are firmly controlled, no matter how long the valve is open, no matter how heavy the weight is, the hammer (the plate) will never fall a trace, to ensure the plate is always open after the open state Flow resistance state), during which no need to fill the oil, make-up measures.

3) off valve: off valve in three cases, A: man-off valve; B: pump or valve failure failure off their own valve; C: loss of off-line off valve. No matter what kind of situation off the valve, just let the electromagnet power loss can be automatically shut down according to a predetermined procedure, electromagnet instantly disappear instantly when electromagnet lose power. Electromagnetic lock shaft once the role of the electromagnetic force is lost immediately unlocked, mechanical lock shaft in the electromagnetic lock axis can unlock the unlocked, then the weight of the hammer that hammer rod, lifting arm, valve shaft and other components driven plate In accordance with the pre-set fast off, buffer, slow off the program for the closing movement, the whole process in one go. During the closing process of the liquid-controlled butterfly valve, the oil in the lower chamber of the lifting cylinder must be excluded. Therefore, the method of controlling and adjusting the discharge speed of the lifting cylinder can effectively control the closing speed of the valve. Liquid-controlled butterfly valve closing process fast off, buffer, slow off three procedures, the fast-off time, slow off time, fast off angle, slow off angle can be adjusted.

Product Parts Materials

|

Model |

D743H-16 |

D743W-16P |

D743W-16R |

|

|

Working pressure(MPa) |

1.6 |

|||

|

Applicable temperature(℃) |

≤425 |

≤200 |

||

|

Suitable media |

Water, oil or non-corrosive media |

Nitric acid medium |

Acetic acid medium |

|

|

Material |

Body, disc |

WCB |

CF8/304 |

CF3M/316L |

|

Valve stem |

2Cr13 |

304 |

316L |

|

|

Body sealing surface |

Surfacing 507 |

- |

- |

|

|

Butterfly sealing surface |

304+Flexible graphite |

304+PTFE |

304+PTFE |

|

|

Filler |

Flexible graphite |

PTFE |

PTFE |

|

The main shape and connection size

|

PN |

DN |

L |

D |

D1 |

D2 |

Z-d |

b |

f |

H |

H0 |

|

1.0 |

50 |

108 |

165 |

125 |

99 |

4-18 |

20 |

2 |

170 |

130 |

|

1.0 |

65 |

112 |

185 |

145 |

118 |

4-18 |

20 |

2 |

170 |

145 |

|

1.0 |

80 |

114 |

200 |

160 |

132 |

8-18 |

20 |

2 |

230 |

152 |

|

1.0 |

100 |

127 |

220 |

180 |

156 |

8-18 |

22 |

2 |

320 |

192 |

|

1.0 |

125 |

140 |

250 |

210 |

184 |

8-18 |

22 |

2 |

345 |

200 |

|

1.0 |

150 |

140 |

285 |

240 |

211 |

8-22 |

24 |

2 |

385 |

230 |

|

1.0 |

200 |

152 |

340 |

295 |

266 |

8-22 |

24 |

2 |

471 |

297 |

|

1.0 |

250 |

165 |

405 |

355 |

319 |

12-22 |

26 |

2 |

533 |

327 |

|

1.0 |

300 |

178 |

445 |

400 |

370 |

12-22 |

26 |

2 |

606 |

364 |

|

1.0 |

350 |

190 |

505 |

460 |

429 |

16-22 |

26 |

2 |

694 |

404 |

|

1.0 |

400 |

216 |

565 |

515 |

480 |

16-26 |

26 |

2 |

757 |

444 |

|

1.0 |

450 |

222 |

615 |

565 |

530 |

20-26 |

28 |

2 |

814 |

472 |

|

1.0 |

500 |

229 |

670 |

620 |

582 |

20-26 |

28 |

2 |

902 |

522 |

|

1.0 |

600 |

267 |

780 |

725 |

682 |

20-30 |

34 |

2 |

1048 |

590 |

|

1.0 |

700 |

292 |

895 |

840 |

794 |

24-30 |

34 |

5 |

1277 |

810 |

|

1.0 |

800 |

318 |

1015 |

950 |

901 |

24-33 |

36 |

5 |

1385 |

844 |

|

1.0 |

900 |

330 |

1115 |

1050 |

1001 |

28-33 |

38 |

5 |

1490 |

890 |

|

1.0 |

1000 |

410 |

1230 |

1160 |

1112 |

28-36 |

38 |

5 |

1620 |

950 |

|

1.6 |

50 |

108 |

165 |

125 |

99 |

4-18 |

20 |

2 |

170 |

130 |

|

1.6 |

65 |

112 |

185 |

145 |

118 |

4-18 |

20 |

2 |

170 |

145 |

|

1.6 |

80 |

114 |

200 |

160 |

132 |

8-18 |

20 |

2 |

230 |

152 |

|

1.6 |

100 |

127 |

220 |

180 |

156 |

8-18 |

22 |

2 |

320 |

192 |

|

1.6 |

125 |

140 |

250 |

210 |

184 |

8-18 |

22 |

2 |

345 |

200 |

|

1.6 |

150 |

140 |

285 |

240 |

211 |

8-22 |

24 |

2 |

385 |

230 |

|

1.6 |

200 |

152 |

340 |

295 |

266 |

12-22 |

24 |

2 |

471 |

297 |

|

1.6 |

250 |

165 |

405 |

355 |

319 |

12-26 |

26 |

2 |

533 |

327 |

|

1.6 |

300 |

178 |

460 |

410 |

370 |

12-26 |

28 |

2 |

606 |

364 |

|

1.6 |

350 |

190 |

520 |

470 |

429 |

16-26 |

30 |

2 |

694 |

404 |

|

1.6 |

400 |

216 |

580 |

525 |

480 |

16-30 |

32 |

2 |

757 |

444 |

|

1.6 |

450 |

222 |

640 |

585 |

548 |

20-30 |

40 |

2 |

814 |

472 |

|

1.6 |

500 |

229 |

715 |

650 |

609 |

20-33 |

44 |

2 |

902 |

522 |

|

1.6 |

600 |

267 |

840 |

770 |

720 |

20-36 |

54 |

2 |

1048 |

590 |

|

1.6 |

700 |

292 |

910 |

840 |

794 |

24-36 |

40 |

5 |

1277 |

810 |

|

1.6 |

800 |

318 |

1025 |

950 |

901 |

24-39 |

42 |

5 |

1385 |

844 |

|

1.6 |

900 |

330 |

1125 |

1050 |

1001 |

28-39 |

44 |

5 |

1490 |

890 |

|

1.6 |

1000 |

410 |

1225 |

1170 |

1112 |

28-42 |

46 |

5 |

1620 |

950 |

|

2.5 |

50 |

108 |

165 |

125 |

99 |

4-18 |

20 |

2 |

170 |

130 |

|

2.5 |

65 |

112 |

185 |

145 |

118 |

8-18 |

22 |

2 |

265 |

210 |

|

2.5 |

80 |

114 |

200 |

160 |

132 |

8-18 |

24 |

2 |

310 |

233 |

|

2.5 |

100 |

127 |

235 |

190 |

156 |

8-22 |

24 |

2 |

343 |

242 |

|

2.5 |

125 |

140 |

270 |

220 |

184 |

8-26 |

26 |

2 |

385 |

254 |

|

2.5 |

150 |

140 |

300 |

250 |

211 |

8-26 |

28 |

2 |

445 |

580 |

|

2.5 |

200 |

152 |

360 |

310 |

274 |

12-26 |

30 |

2 |

510 |

297 |

|

2.5 |

250 |

165 |

425 |

370 |

330 |

12-30 |

32 |

2 |

569 |

339 |

|

2.5 |

300 |

178 |

485 |

430 |

389 |

16-30 |

34 |

2 |

653 |

375 |

|

2.5 |

350 |

190 |

555 |

490 |

448 |

16-33 |

38 |

2 |

730 |

420 |

|

2.5 |

400 |

216 |

620 |

550 |

503 |

16-36 |

40 |

2 |

810 |

463 |

|

2.5 |

450 |

222 |

670 |

600 |

548 |

20-36 |

46 |

2 |

850 |

495 |

|

2.5 |

500 |

229 |

730 |

660 |

609 |

20-36 |

48 |

2 |

940 |

566 |

|

2.5 |

600 |

267 |

845 |

770 |

720 |

20-39 |

58 |

2 |

1150 |

630 |

|

2.5 |

700 |

292 |

960 |

875 |

820 |

24-42 |

58 |

5 |

1195 |

727 |

|

2.5 |

800 |

318 |

1085 |

990 |

609 |

24-36 |

58 |

5 |

1268 |

810 |

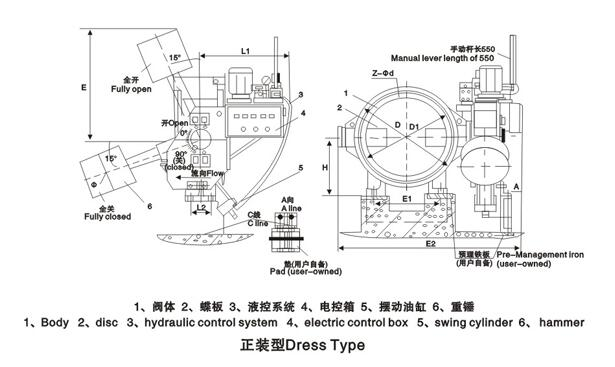

Structure picture

If you have any enquiry about quotation or cooperation,please feel free to email us at info@cnlgvalve.com or use the following enquiry form. Our sales representative will contact you within 24 hours. Thank you for your interest in our products.