The J41H and J41Y high temperature and high pressure globe valves produced by Lianggu valve Co., Ltd. are suitable for the pipelines of various systems in petroleum, chemical, hydraulic and thermal power plants with a nominal pressure of 150LB to 2500LB and an operating temperature of 570 ℃. Pipeline medium.

Product Usage

The J41H and J41Y high temperature and high pressure globe valves produced by Lianggu valve Co., Ltd. are suitable for the pipelines of various systems in petroleum, chemical, hydraulic and thermal power plants with a nominal pressure of 150LB to 2500LB and an operating temperature of 570 ℃. Pipeline medium.

Features

1. The valve cavity adopts pressure self-tightening sealing structure, the better the sealing performance. Both ends of the branch pipe are welded structures. Welding groove can be matched according to standard or user requirements

2. The sealing surfaces of the valve disc and valve seat are made of Stellite cobalt-based hard alloy, which is wear-resistant, high-temperature resistant, good scratch resistance and long service life

3. The valve stem is tempered and surface nitridized, which has good corrosion resistance and scratch resistance.

4. The depth of the stuffing box of the valve cover is reasonable, the filler is added with corrosion inhibitor, and the sealing is reliable

Design Standard: ASME B16.34

Structure Length: SME B16.10

Test and Inspection: API 598

Pressure - Temperature: ASME B16.34

Product Identification: ASME B16.34

Performance Parameters

|

Nominal pressure |

150LB |

300LB |

600LB |

900LB |

1500LB |

2500LB |

|

|

Work pressure |

2.0 |

5.0 |

10.0 |

15.0 |

25.0 |

45.0 |

|

|

proper temperature(℃) |

≤570 |

≤570 |

≤570 |

≤570 |

≤570 |

≤570 |

|

|

Suitable media |

Steam and other high temperature and high pressure value |

||||||

|

material |

Body, bonnet |

Chromium molybdenum vanadium steel |

|||||

|

Disc |

Chromium molybdenum vanadium steel + hardfacing alloy |

||||||

|

Seat |

Chromium molybdenum vanadium steel + hardfacing alloy |

||||||

|

Valve stem |

Chromium molybdenum vanadium steel |

||||||

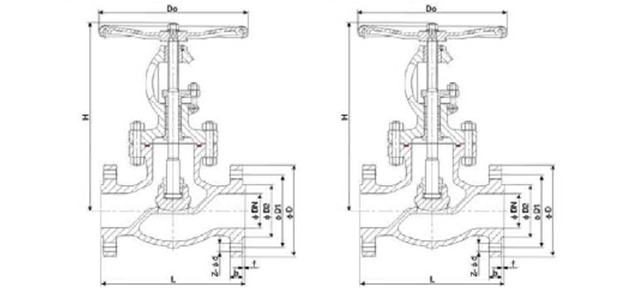

The main shape and connection size

|

DN |

L |

D |

D1 |

D2 |

f |

b |

z-Φd |

H |

D0 |

|

150(LB) |

|||||||||

|

DN15 |

108 |

90 |

60.3 |

35 |

2 |

8 |

4-Φ16 |

235 |

125 |

|

DN20 |

117 |

100 |

70 |

43 |

2 |

9 |

4-Φ16 |

241 |

125 |

|

DN25 |

127 |

110 |

79.4 |

51 |

2 |

9.6 |

4-Φ16 |

242 |

125 |

|

DN32 |

140 |

115 |

89 |

63.5 |

2 |

11.2 |

4-Φ16 |

280 |

160 |

|

DN40 |

165 |

125 |

98.4 |

73 |

2 |

12.7 |

4-Φ16 |

315 |

160 |

|

DN50 |

203 |

150 |

120.7 |

92 |

2 |

14.3 |

4-Φ19 |

350 |

200 |

|

DN65 |

216 |

180 |

139.7 |

105 |

2 |

15.9 |

4-Φ19 |

370 |

200 |

|

DN80 |

241 |

190 |

152.4 |

127 |

2 |

17.5 |

4-Φ19 |

385 |

250 |

|

DN100 |

292 |

230 |

190.5 |

157.2 |

2 |

22.3 |

8-Φ19 |

454 |

250 |

|

DN125 |

356 |

255 |

216 |

185.7 |

2 |

22.3 |

8-Φ22.5 |

472 |

355 |

|

DN150 |

406 |

280 |

241.5 |

216 |

2 |

23.9 |

8-Φ22.5 |

541 |

355 |

|

DN200 |

495 |

345 |

298.5 |

270 |

2 |

27 |

8-Φ22.5 |

590 |

450 |

|

DN250 |

622 |

405 |

362 |

324 |

2 |

28.6 |

12-Φ25.5 |

780 |

450 |

|

DN300 |

698 |

485 |

438 |

381 |

2 |

30.2 |

12-Φ25.5 |

870 |

500 |

|

DN350 |

787 |

535 |

476.3 |

413 |

2 |

33.4 |

12-Φ28.5 |

900 |

600 |

|

DN400 |

914 |

595 |

540 |

470 |

2 |

35 |

16-Φ28.5 |

1250 |

600 |

|

DN450 |

- |

635 |

578 |

533.4 |

2 |

38.1 |

16-Φ32 |

- |

610 |

|

300(LB) |

|||||||||

|

DN15 |

152 |

95 |

66.7 |

35 |

2 |

12.7 |

4-Φ16 |

241 |

125 |

|

DN20 |

178 |

115 |

82.6 |

43 |

2 |

14.3 |

4-Φ19 |

241 |

125 |

|

DN25 |

203 |

125 |

89 |

50.8 |

2 |

15.9 |

4-Φ19 |

283 |

160 |

|

DN32 |

216 |

135 |

98.5 |

63.5 |

2 |

17.5 |

4-Φ19 |

320 |

200 |

|

DN40 |

229 |

155 |

114.3 |

73 |

2 |

19.1 |

4-Φ22.5 |

322 |

200 |

|

DN50 |

267 |

165 |

127 |

92.1 |

2 |

20.7 |

8-Φ19 |

345 |

200 |

|

DN65 |

292 |

190 |

149.2 |

104.8 |

2 |

23.9 |

8-Φ22.5 |

377 |

250 |

|

DN80 |

318 |

210 |

168.3 |

127 |

2 |

27 |

8-Φ22.5 |

464 |

280 |

|

DN100 |

356 |

255 |

200 |

157.2 |

2 |

30.2 |

8-Φ22.5 |

490 |

355 |

|

DN125 |

400 |

280 |

235 |

185.7 |

2 |

33.4 |

8-Φ22.5 |

614 |

400 |

|

DN150 |

444 |

320 |

270 |

216 |

2 |

35 |

12-Φ22.5 |

700 |

450 |

|

DN200 |

559 |

380 |

330.2 |

270 |

2 |

39.7 |

12-Φ25.5 |

777 |

500 |

|

DN250 |

622 |

445 |

387.4 |

323.8 |

2 |

46.1 |

16-Φ28.5 |

935 |

550 |

|

DN300 |

711 |

520 |

450.8 |

381 |

2 |

49.3 |

16-Φ32 |

997 |

600 |

|

DN350 |

762 |

585 |

514.4 |

412.8 |

2 |

52.4 |

20-Φ32 |

1058 |

650 |

|

DN400 |

864 |

650 |

571.5 |

470 |

2 |

55.6 |

20-Φ35 |

1320 |

700 |

|

600(LB) |

|||||||||

|

DN15 |

165 |

95 |

66.7 |

35 |

7 |

14.3 |

4-Φ16 |

245 |

156 |

|

DN20 |

190 |

115 |

82.6 |

43 |

7 |

15.9 |

4-Φ19 |

245 |

161 |

|

DN25 |

216 |

125 |

89 |

50.8 |

7 |

17.5 |

4-Φ19 |

290 |

187 |

|

DN32 |

229 |

135 |

98.4 |

63.5 |

7 |

20.7 |

4-Φ19 |

325 |

214 |

|

DN40 |

241 |

155 |

114.3 |

73 |

7 |

22.3 |

4-Φ22.5 |

330 |

252 |

|

DN50 |

292 |

165 |

127 |

92.1 |

7 |

25.4 |

8-Φ19 |

345 |

430 |

|

DN65 |

330 |

190 |

149.2 |

104.8 |

7 |

28.6 |

8-Φ22.5 |

365 |

480 |

|

DN80 |

356 |

210 |

168.3 |

127 |

7 |

31.8 |

8-Φ22.5 |

465 |

530 |

|

DN100 |

432 |

275 |

216 |

157 |

7 |

38.1 |

8-Φ25.5 |

520 |

650 |

|

DN125 |

508 |

330 |

266.7 |

185.7 |

7 |

44.5 |

8-Φ28.5 |

635 |

750 |

|

DN150 |

559 |

355 |

292.1 |

216 |

7 |

47.7 |

12-Φ28.5 |

763 |

850 |

|

DN200 |

660 |

420 |

349.2 |

270 |

7 |

55.6 |

12-Φ32 |

845 |

1050 |

|

DN250 |

787 |

510 |

431.8 |

323.8 |

7 |

63.5 |

16-Φ35 |

930 |

1257 |

|

DN300 |

838 |

560 |

489 |

381 |

7 |

66.7 |

20-Φ35 |

1010 |

1468 |

|

DN350 |

889 |

605 |

527 |

412.8 |

7 |

69.9 |

20-Φ38 |

1090 |

1623 |

|

DN400 |

991 |

685 |

603.2 |

470 |

7 |

76.2 |

20-Φ41 |

1140 |

1816 |

|

900(LB) |

|||||||||

|

DN50 |

368 |

215 |

165.1 |

92.1 |

7 |

38.1 |

8-Φ25.5 |

430 |

320 |

|

DN65 |

419 |

245 |

190.5 |

104.8 |

7 |

41.3 |

8-Φ28.5 |

530 |

320 |

|

DN80 |

381 |

265 |

190.5 |

127 |

7 |

38.1 |

8-Φ28.5 |

580 |

360 |

|

DN100 |

457 |

290 |

235 |

157.2 |

7 |

44.5 |

8-Φ32 |

690 |

450 |

|

DN125 |

559 |

350 |

279.4 |

185.7 |

7 |

50.8 |

8-Φ35 |

780 |

560 |

|

DN150 |

610 |

380 |

317.5 |

216 |

7 |

55.6 |

12-Φ32 |

890 |

630 |

|

DN200 |

737 |

470 |

393.7 |

270 |

7 |

63.5 |

12-Φ38 |

1240 |

720 |

|

DN250 |

838 |

545 |

470 |

323.8 |

7 |

69.9 |

16-Φ38 |

1651 |

760 |

|

1500(LB) |

|||||||||

|

DN65 |

419 |

245 |

190.5 |

104.8 |

7 |

41.6 |

8-Φ28.5 |

530 |

400 |

|

DN80 |

470 |

265 |

203.2 |

127 |

7 |

47.7 |

8-Φ32 |

590 |

450 |

|

DN100 |

546 |

310 |

241.3 |

157.2 |

7 |

54 |

8-Φ35 |

710 |

500 |

|

DN125 |

673 |

375 |

292.1 |

185.7 |

7 |

73.1 |

8-Φ41 |

780 |

560 |

|

DN150 |

705 |

395 |

317.5 |

215.9 |

7 |

82.6 |

12-Φ38 |

904 |

630 |

|

DN200 |

832 |

485 |

393.7 |

270 |

7 |

92.1 |

12-Φ45 |

1140 |

560 |

|

2500(LB) |

|||||||||

|

DN65 |

508 |

265 |

196.8 |

104.8 |

7 |

57.2 |

8-Φ32 |

740 |

400 |

|

DN80 |

578 |

305 |

228.6 |

127 |

7 |

66.7 |

8-Φ35 |

780 |

450 |

|

DN100 |

637 |

355 |

273 |

157.2 |

7 |

76.2 |

8-Φ41 |

860 |

560 |

|

DN125 |

794 |

420 |

323.8 |

185.7 |

7 |

92.1 |

8-Φ48 |

930 |

630 |

|

DN150 |

914 |

485 |

368.3 |

216 |

7 |

108 |

8-Φ54 |

1070 |

560 |

|

DN200 |

1022 |

550 |

438.2 |

270 |

7 |

127 |

12-Φ54 |

1180 |

630 |

Structure picture

If you have any enquiry about quotation or cooperation,please feel free to email us at info@cnlgvalve.com or use the following enquiry form. Our sales representative will contact you within 24 hours. Thank you for your interest in our products.