Liang valve Industrial Group Co., Ltd. production of flat gate valve, is a kind of sliding piece sliding shutter for the parallel. The closing member can be a single gate or a double gate with a distraction mechanism therebetween. The pressing force of the gate to the valve seat is controlled by the medium pressure acting on the floating gate or the floating valve seat. If it is a double gate plate gate valve, then the two gates between the distraction mechanism can supplement this pressure.

Product Usage

The flat gate valve produced by Lianggu Valve Group Co., Ltd. is a sliding valve whose closing part is a parallel gate. The closing member can be a single gate or a double gate with a distraction mechanism in between. The pressing force of the gate to the valve seat is controlled by the medium pressure acting on the floating gate or the floating valve seat. If it is a double gate plate gate valve, the expansion mechanism between the two gates can supplement this pressing force.

Product Categories

The flat gate valve can be divided into manual flat gate valve, pneumatic flat gate valve and electric flat gate valve according to the driving mode. According to the use and occasion, it can be divided into diversion hold flat gate valve, non-diversion hole flat gate valve, oil field flat gate valve, pipeline flat gate valve, gas flat gate valve, etc.

Structural Features

This series of products adopt the new floating seal structure, which is suitable for the opening, closing and adjusting devices of control media such as oil and natural gas with pressure less than 15.0MPa and temperature from -29 ℃ to 121 ℃. The product has a novel structural design and material selection. Appropriate, rigorous test, light operation, strong anti-corrosion, abrasion resistance and erosion resistance. It is an ideal new equipment in the petroleum industry.

1. Adopting floating valve seat, two-way opening and closing, reliable sealing and flexible opening and closing.

2. The gate is provided with guide strips for precise guidance, and the sealing surface is spray welded with carbide, which is resistant to erosion.

3. The valve body has a high load-bearing capacity and the channel is straight-through. When fully opened, it is similar to the gate diversion hole and the straight pipe, and the flow resistance is very small. The valve stem adopts composite filler, multiple seals, making the seal reliable and low friction.

4. When closing the valve, turn the handwheel clockwise to move the shutter down to the bottom. Due to the pressure of the medium, the inlet seal seat is pushed towards the direction of the shutter to form a larger seal specific pressure, thus forming the first seal. At the same time, the shutter is pressed against the sealing seat at the outlest end to become a double seal.

5. Due to the double seal, the consumable parts can be replaced without affecting the work of the pipeline. This is an important feature that our products take priority over similar products at home and abroad.

6. When the gate is open, turn the hand wheel counterclockwise, the gate moved up, and the diversion hole and channel hole intersect. With the rise of the gate, the through hole gradually increases, and when the limit position is reached, the diversion hole and the passage hole coincide, and they are fully opened at this time.

Design Standards

Design and manufacture of standards: JB / T 5298

Structure length standard: JB / T 5298

Connection flange standard: GB / T 9113

Pressure temperature grade: GB / T 12224-2005

Test test standards: GB / T 13927-2008, JB / T 5298

Performance Parameters

|

Part Name |

Parts and materials |

|||

|

JB/T77298 |

API 6D |

|||

|

Valve / bonnet |

WCB |

WCB |

A352-LCB |

A351-CF8N |

|

gate |

2Cr13+ENP |

20CrMoV+STL |

ANSI 410+ENP |

ANSI 316+ENP |

|

Valve stem |

2Cr13 |

2Cr13 |

A182-F6a |

A182-F316S |

|

Seat |

25+PTFE |

20CrMoV+STL |

A105+PTFE |

A182-F316+PTFE |

|

filler |

NBR/FPM |

Flexible graphite |

Teflon |

|

|

Gasket |

18-8 / Flexible Graphite |

|||

|

bolt |

35 |

35CrMo |

A193-B7M |

A193-B8 |

|

proper temperature |

-29~250℃ |

-29~550℃ |

-46~250℃ |

-40~200℃ |

|

Suitable media |

Water, oil |

Steam, oil |

Propane, ethylene |

Nitric acids |

The main shape and connection dimensions

|

Nominal diameter |

The main dimensions and connection dimensions |

||||||

|

L |

D |

D1 |

D2 |

Z-Φd |

H |

D0 |

|

|

Z43PF-16C |

|||||||

|

100 |

150 |

215 |

180 |

155 |

8-Φ18 |

700 |

300 |

|

125 |

150 |

245 |

210 |

185 |

8-Φ18 |

798 |

350 |

|

150 |

150 |

280 |

240 |

210 |

8-Φ23 |

895 |

350 |

|

200 |

180 |

335 |

295 |

265 |

12-Φ23 |

1130 |

350 |

|

250 |

180 |

405 |

355 |

320 |

12-Φ25 |

1290 |

400 |

|

300 |

200 |

460 |

410 |

375 |

12-Φ25 |

1480 |

450 |

|

350 |

200 |

520 |

470 |

435 |

16-Φ25 |

1660 |

450 |

|

400 |

218 |

580 |

525 |

485 |

16-Φ30 |

1850 |

500 |

|

450 |

218 |

640 |

585 |

545 |

20-30 |

2080 |

500 |

|

500 |

229 |

705 |

650 |

608 |

20-34 |

2300 |

600 |

|

600 |

248 |

840 |

770 |

718 |

20-41 |

2680 |

800 |

|

700 |

286 |

910 |

840 |

788 |

24-41 |

3080 |

800 |

|

800 |

286 |

1020 |

950 |

898 |

24-41 |

3491 |

1000 |

|

Z43PF-25 |

|||||||

|

100 |

150 |

230 |

190 |

160 |

8-Φ23 |

700 |

300 |

|

125 |

150 |

270 |

220 |

188 |

8-Φ25 |

798 |

350 |

|

150 |

150 |

300 |

250 |

218 |

8-Φ25 |

895 |

350 |

|

200 |

180 |

360 |

310 |

278 |

12-Φ25 |

1130 |

350 |

|

250 |

180 |

425 |

370 |

332 |

12-Φ30 |

1290 |

400 |

|

300 |

200 |

485 |

430 |

390 |

16-Φ30 |

1480 |

450 |

|

350 |

200 |

550 |

490 |

448 |

16-Φ34 |

1660 |

450 |

|

400 |

218 |

610 |

550 |

505 |

16-Φ34 |

1850 |

500 |

|

450 |

218 |

660 |

600 |

555 |

20-Φ34 |

2080 |

500 |

|

500 |

229 |

730 |

660 |

610 |

20-Φ41 |

2300 |

600 |

|

600 |

248 |

840 |

770 |

718 |

20-Φ41 |

2680 |

800 |

|

700 |

286 |

955 |

875 |

815 |

24-Φ48 |

3080 |

800 |

|

800 |

286 |

1070 |

990 |

930 |

24-Φ48 |

3491 |

1000 |

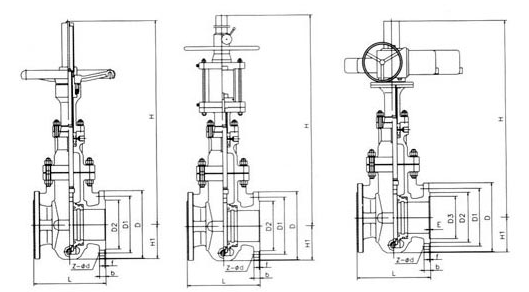

Structure picture

If you have any enquiry about quotation or cooperation,please feel free to email us at info@cnlgvalve.com or use the following enquiry form. Our sales representative will contact you within 24 hours. Thank you for your interest in our products.