D341H, D341W PN0.5 ~ PN1 Ventilation Butterfly Valve Regulates the flow or cut-off device as a gas medium in dusty cold air or hot-air gas pipes for ventilation and environmental projects in metallurgy, chemical industry, building materials, power plants and glass industries.

Product Usage

D341H, D341W PN0.5 ~ PN1 Ventilation Butterfly Valve Regulates the flow or cut-off device as a gas medium in dusty cold air or hot-air gas pipes for ventilation and environmental projects in metallurgy, chemical industry, building materials, power plants and glass industries.

Features

The structure of the ventilation butterfly valve is welded by using the mid-line butterfly plate and the short-structure steel plate. Therefore, there are no components such as connecting rods and bolts in the interior of the butterfly valve and no component problems occur during use. Therefore, the failure rate is very low. Very easy to use. Is a reliable valve device. And because its sealing system uses a metal seal, although the sealing effect is not as flexible seal, but the service life is longer than the flexible seal, and has high temperature characteristics. So in building materials, electricity, metallurgy and other industries have a wide range of applications. In the medium temperature of not more than 300 degrees pipeline, can be the perfect connection and closing adjustment. This butterfly valve can also be customized according to customer needs, very user-friendly.

Because the butterfly valve butterfly valve body and the gap between the large, there is enough room for expansion, so in the course of its use can effectively prevent the temperature change due to thermal expansion and contraction of the situation, it will not produce the butterfly Card stuck phenomenon. There are a variety of common butterfly valve drive, a manual drive, there are electric drive and pneumatic drive, etc., the choice of a very large room. Because of the material reason, this kind of butterfly valve also possesses the characteristic of the high temperature, when the switch will not have the friction, the service life is very long. Ventilated butterfly valve is a valve made of welded steel plate, it has the characteristics of small size, light weight and easy installation, but also because of its small flow resistance, large flow, will not be affected by high temperature expansion. Its driving torque is small, the switch is very flexible, so it is easy to operate. By the industry's favorite.

Installation Notes

Ventilation butterfly valve installation is crucial, because the installation is directly related to the quality of machinery used, so we must be careful when installing the ventilation butterfly valve, and pay attention to the relevant issues! Here Xiaotian Xiaobian take everyone together to explore it!

The structure of the ventilation butterfly valve is designed and manufactured with a new type of structure welded by a midline dish and a short structural steel plate. The utility model has the advantages of compact structure, light weight, convenient installation, small flow resistance, large flow, avoiding the influence of high temperature expansion and convenient operation. Ventilation butterfly valve without connecting rods, bolts, etc., reliable, long service life. Ventilation butterfly valve is a non-closed butterfly valve, widely used in building materials, metallurgy, mining, electricity and other production processes of medium temperature ≤ 300 ℃ Nominal pressure of 0.1Mpa pipeline, to connect, open or close or adjust the media volume.

Ventilation butterfly valves should be installed horizontally in pipelines in general, and should be used in the dusty cold air or hot air ducts for ventilation and environmental protection projects in chemical industry, building materials, power stations and glass industries, and to be used as the pipeline control device for regulating the flow rate or cutting off of the gas medium.

Product main parameters

|

Nominal pressure(MPa) |

0.05MPa |

Medium temperature |

-30℃~-350℃ |

|

Strength test |

0.1MPa |

Suitable media |

Hot and cold wind, smoke |

|

Medium flow rate |

25m/s |

Leak rate |

3% |

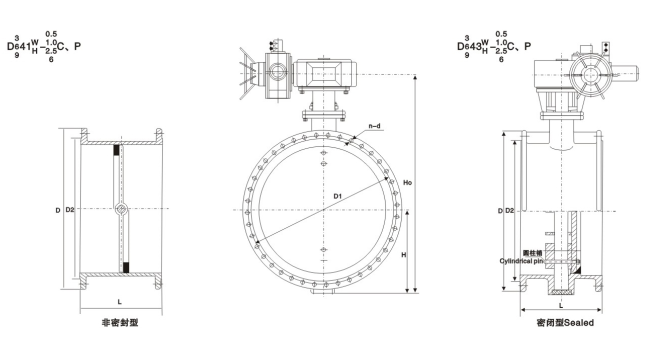

The main shape and connection size

|

DN |

D |

D1 |

L |

L1 |

L2 |

n-Фd |

b |

|

300 |

405 |

370 |

120 |

716 |

220 |

8-12 |

10 |

|

350 |

455 |

420 |

140 |

786 |

240 |

8-14 |

10 |

|

400 |

505 |

470 |

140 |

924 |

270 |

12-18 |

10 |

|

450 |

570 |

530 |

160 |

999 |

295 |

12-18 |

10 |

|

500 |

620 |

580 |

160 |

1079 |

325 |

12-18 |

10 |

|

600 |

720 |

680 |

180 |

1140 |

380 |

16-18 |

12 |

|

700 |

820 |

780 |

180 |

1240 |

430 |

16-18 |

12 |

|

800 |

920 |

880 |

200 |

1350 |

490 |

16-18 |

12 |

|

900 |

1040 |

990 |

200 |

1450 |

540 |

16-18 |

14 |

|

1000 |

1140 |

1090 |

220 |

1550 |

590 |

20-18 |

14 |

|

1100 |

1240 |

1190 |

220 |

1800 |

640 |

20-18 |

14 |

|

1200 |

1340 |

1290 |

240 |

1900 |

690 |

20-18 |

14 |

|

1300 |

1440 |

1390 |

240 |

2020 |

760 |

20-18 |

16 |

|

1400 |

1540 |

1490 |

260 |

2120 |

810 |

24-18 |

16 |

|

1500 |

1640 |

1590 |

260 |

2220 |

860 |

24-18 |

16 |

|

1600 |

1740 |

1690 |

280 |

2390 |

980 |

24-18 |

16 |

|

1700 |

1840 |

1790 |

280 |

2590 |

1030 |

28-22 |

16 |

|

1800 |

1940 |

1890 |

300 |

2709 |

1096 |

28-22 |

16 |

|

1900 |

2040 |

1990 |

300 |

2826 |

1146 |

32-22 |

16 |

|

2000 |

2150 |

2090 |

320 |

2926 |

1196 |

32-26 |

16 |

|

2200 |

2360 |

2300 |

340 |

3126 |

1296 |

36-26 |

16 |

|

2400 |

2560 |

2500 |

360 |

3326 |

1396 |

36-26 |

18 |

|

2600 |

2760 |

2700 |

380 |

3526 |

1496 |

40-26 |

18 |

|

2800 |

2960 |

2900 |

400 |

3726 |

1596 |

40-26 |

18 |

|

3000 |

3190 |

3110 |

400 |

4098 |

1698 |

44-30 |

18 |

|

3200 |

3390 |

3310 |

440 |

4338 |

1798 |

44-30 |

20 |

|

3400 |

3590 |

3510 |

440 |

4578 |

1898 |

48-30 |

20 |

|

3600 |

3790 |

3710 |

480 |

4780 |

1998 |

48-30 |

20 |

|

3800 |

4000 |

3910 |

480 |

5000 |

2098 |

52-30 |

22 |

|

4000 |

4210 |

4120 |

520 |

5200 |

2210 |

52-30 |

22 |

Structure picture

If you have any enquiry about quotation or cooperation,please feel free to email us at info@cnlgvalve.com or use the following enquiry form. Our sales representative will contact you within 24 hours. Thank you for your interest in our products.